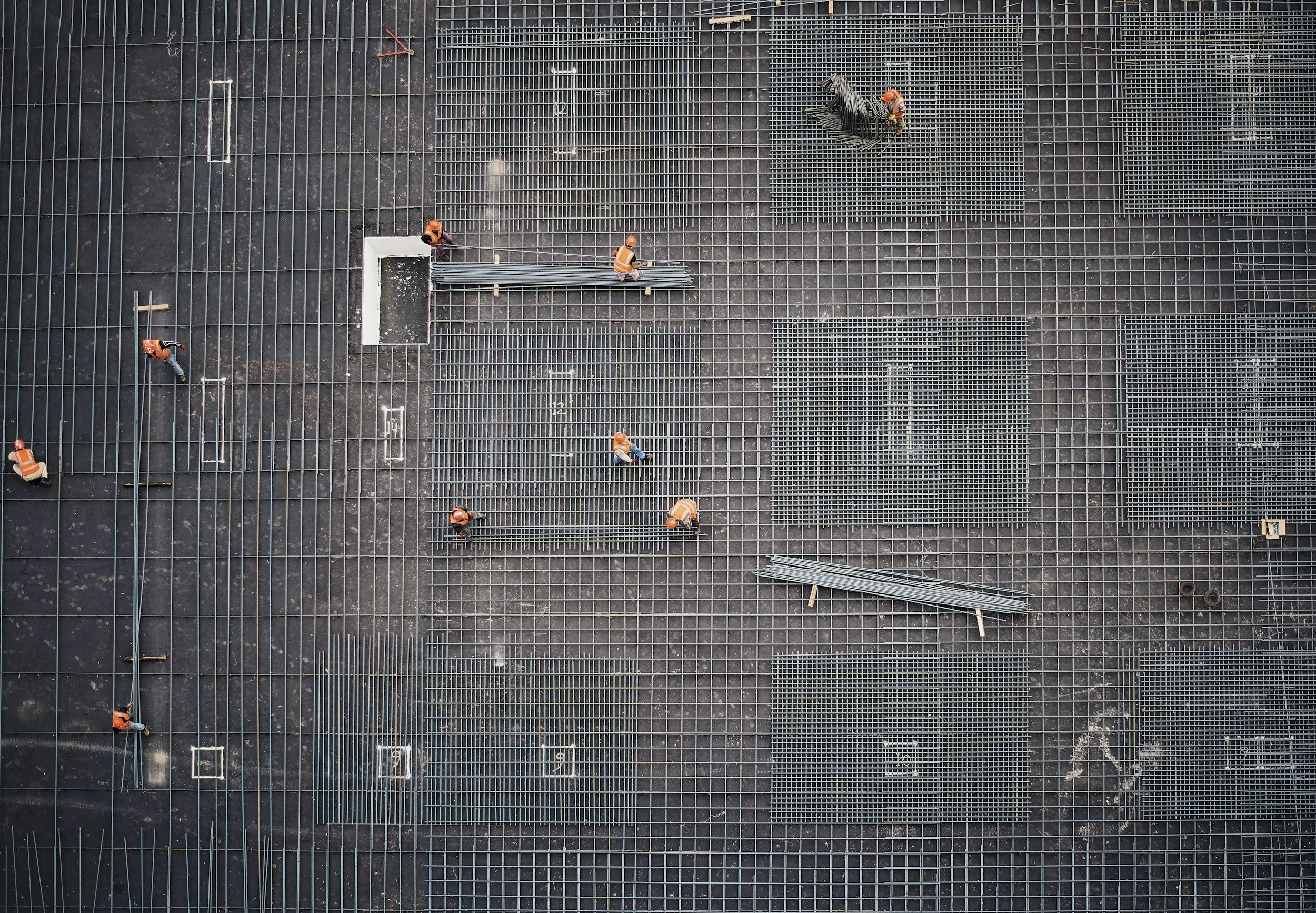

Construction Projects: 2024-2026

Our Proud Partners:

Vertical integration in general contracting refers to the process of consolidating various stages of the construction process under one organizational umbrella. By integrating multiple functions such as design, procurement, construction, and even maintenance, a general contractor can significantly streamline operations and enhance overall efficiency. Here’s how vertical integration can achieve these goals:

Iron Render GC:

Unified Project Management: A single point of contact for all project phases ensures that everyone is on the same page. This coordination helps in aligning goals, timelines, and expectations, leading to a smoother workflow.

Standardized Processes: By managing all aspects of the construction process, the contractor can implement standardized procedures and best practices. This leads to a more predictable and reliable outcome, reducing the risk of errors and rework.

Efficient Scheduling: With all project phases controlled by a single entity, scheduling becomes more efficient. There is no need to coordinate between multiple external contractors, which often leads to delays. Integrated project management ensures that each phase transitions smoothly into the next.

Reduced Overheads: By eliminating the need to outsource various project components, the contractor can reduce overhead costs associated with subcontractor management, negotiations, and third-party fees.

Core Excavation:

Internal Labor Force: Employing an in-house team of concrete specialists allows the general contractor to better control labor costs. This team can be utilized across multiple projects, providing flexibility and cost efficiency compared to hiring external labor for each project.

Elimination of Markup: External contractors typically add a markup on labor costs to cover their overheads and profit margins. By handling concrete work in-house, the general contractor avoids these additional charges.

Investing In Long-Term Innovation: Investing in the training and development of an in-house concrete team enhances their skills and expertise over time. This investment leads to higher productivity and better quality work, yielding long-term savings. In-house teams can adopt new technologies and innovative methods more rapidly, improving efficiency and reducing costs.

Axis Concrete Solutions:

Internal Labor Force: Employing an in-house team of concrete specialists allows the general contractor to better control labor costs. This team can be utilized across multiple projects, providing flexibility and cost efficiency compared to hiring external labor for each project.

Reduced Markup: External contractors typically add a markup on labor costs to cover their overheads and profit margins. By handling concrete work in-house, the general contractor avoids these additional charges.

Investing In Long-Term Innovation: Investing in the training and development of an in-house concrete team enhances their skills and expertise over time. This investment leads to higher productivity and better quality work, yielding long-term savings. In-house teams can adopt new technologies and innovative methods more rapidly, improving efficiency and reducing costs.